Website no longer active. Please use our new website Tegiwa.com

Details

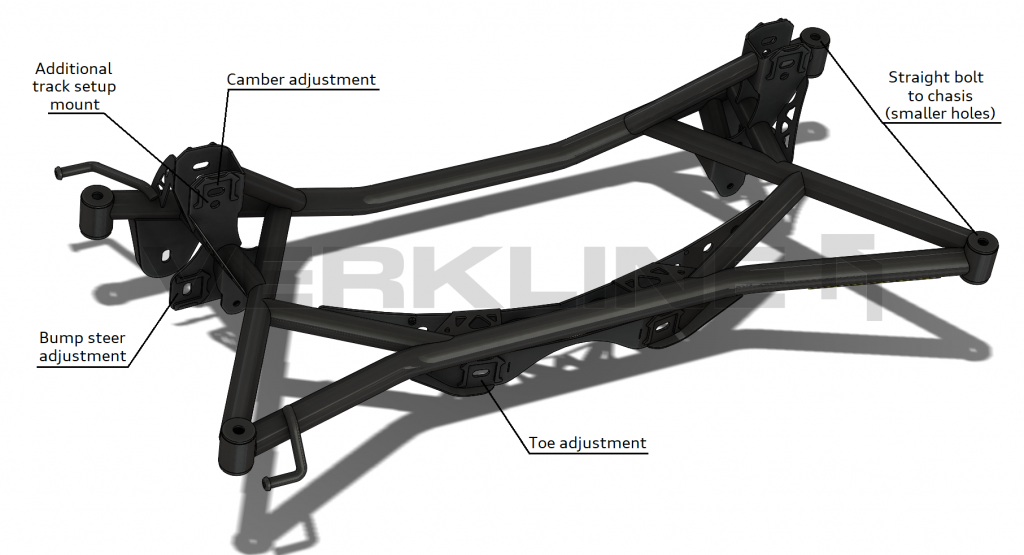

After long CAD development based on 3D scan of OEM subframe, tested with CAD FEA (Finite element method) and road going tests you can now buy brand subframe for rear of your Audi/VW/SEAT/Skoda cars based on MQB platform Front Wheel Drive cars.

Using same T45 tubing as in WRC cars, our subframes provide increased stiffness and mass reduction. All factory parts bolt up to this unit, no other modifications are necessary.

Benefits:

– 11 kg. It is 2 kg saving over OEM steel subframe.

– Possibility of adjusting camber, toe and bump steer for improved suspension kinematics.

– Additional mounting for upper control arm – provides better camber gain and roll center

position (requires adjustable control arm to keep camber adjustment).

– One mounting subframe position, eliminates subframe shifting under the car. No need for subframe

locking kit / billet aluminium rear subframe inserts (weight savings).

– Increases chassis rigidity for improved handling performance.

Features:

– better access to car under body and enables wishbones change without subframe removal

– T45 (BS4T45 to BS4T100) tubing imported from UK and S355 metal sheets

– all components TIG welded

– delivered painted (powder coated) black or on special order (+50 euro) any RAL color

– can be used with OEM wishbones or our adjustable wishbones

– mounts to the OEM car body and no other modifications are needed to fit the subframe

– includes mounts for two OEM rear xenon lights sensors

– can be used with exhaust up to 4 inch. OEM positioning.

– no need for subframe inserts or our aluminium subframe bushings as the subframe comes with solid mounts to the car body

What is included:

– rear subframe powder coated in back.

– 3 mm metal adjustable wishbone position shims

Used in PQ35 and MQB platform cars (Type numbers in brackets):

Audi A3/3 (8P & 8V & 8VFL 2012+) FWD

Audi TT/TTS (8J & 8S 2006+) FWD

SEAT León Mk3 (5F) (2006-2013) FWD

VW Golf Mk5 Mk6 Mk7 (2003+) FWD

T45 is a very unique seamless carbon based steel tube that has been used in many applications in different industries. It is stronger than Co-Mo 4130 tubing that also used in motorsport. It is widely used in the aerospace sector in equipment such as pilot’s seats and crew’s seats due to the materials ability to withstand high G forces without snapping or splitting. This material is a Carbon Manganese based and conforms to the full Aerospace Specification laid down by British Standards.

Properties

Tensile: 700 – 900MPa,

0.2% Yield 620MPa minimum

Hardness Test: 201min – 262 max HB or 210min – 275max HV.

Replaces:

– 1K0 505 315 BH /BM /H

– 5Q0 505 315 G /H

– 5N0 505 315 B /AB /G

Notice: Sold for off road, track and racing applications only. Mounting the subframe may increase some noise, vibration, and harshness (NVH) in the car. We strongly advice to mount the subframe in qualified and experienced workshop.

Additional Information

| Manufacturer | Verkline |

|---|---|

| Fitment | See description |

| Color | N/A |

| Note | No |

- Be the first to review this product

Write Your Own Review

You may also be interested in

Verkline Rear Lightweight Tubular Subframe BMW Z4 G29/Toyota A90 Supra

£2,290.27 Excl. Tax £2,748.32 Incl. Tax